The Townsend WTP Electrical Improvements Phase 2 project, underway in Greensboro, North Carolina, included major structural and mechanical rehabilitation to an existing high-lift pump station. PC’s scope of work included demolition of more than 400 cubic yards of existing concrete structural supports, walls and slabs; demolition of 50% of the existing flanged ductile iron piping ranging in diameter from 6 inches to 48 inches; and removal of three existing dual-stage, split-case high-lift pumps, each rated between 1,200- and 2,500-horsepower.

The Townsend WTP Electrical Improvements Phase 2 project, underway in Greensboro, North Carolina, included major structural and mechanical rehabilitation to an existing high-lift pump station. PC’s scope of work included demolition of more than 400 cubic yards of existing concrete structural supports, walls and slabs; demolition of 50% of the existing flanged ductile iron piping ranging in diameter from 6 inches to 48 inches; and removal of three existing dual-stage, split-case high-lift pumps, each rated between 1,200- and 2,500-horsepower.

The early phases made space for the new pump station work, which featured new structural steel framing and an elevated operating floor slab, installation of 24-inch and 48-inch suction pipe and discharge lines and four 800-horsepower vertical turbine high-lift pumps. All this work was successfully completed through more than 10 planned shutdowns, with each shutdown having a specific timeframe to maintain overall water production demands.

Many key planning measures were implemented to safely and successfully complete this work – all within or ahead of the available shutdown windows.

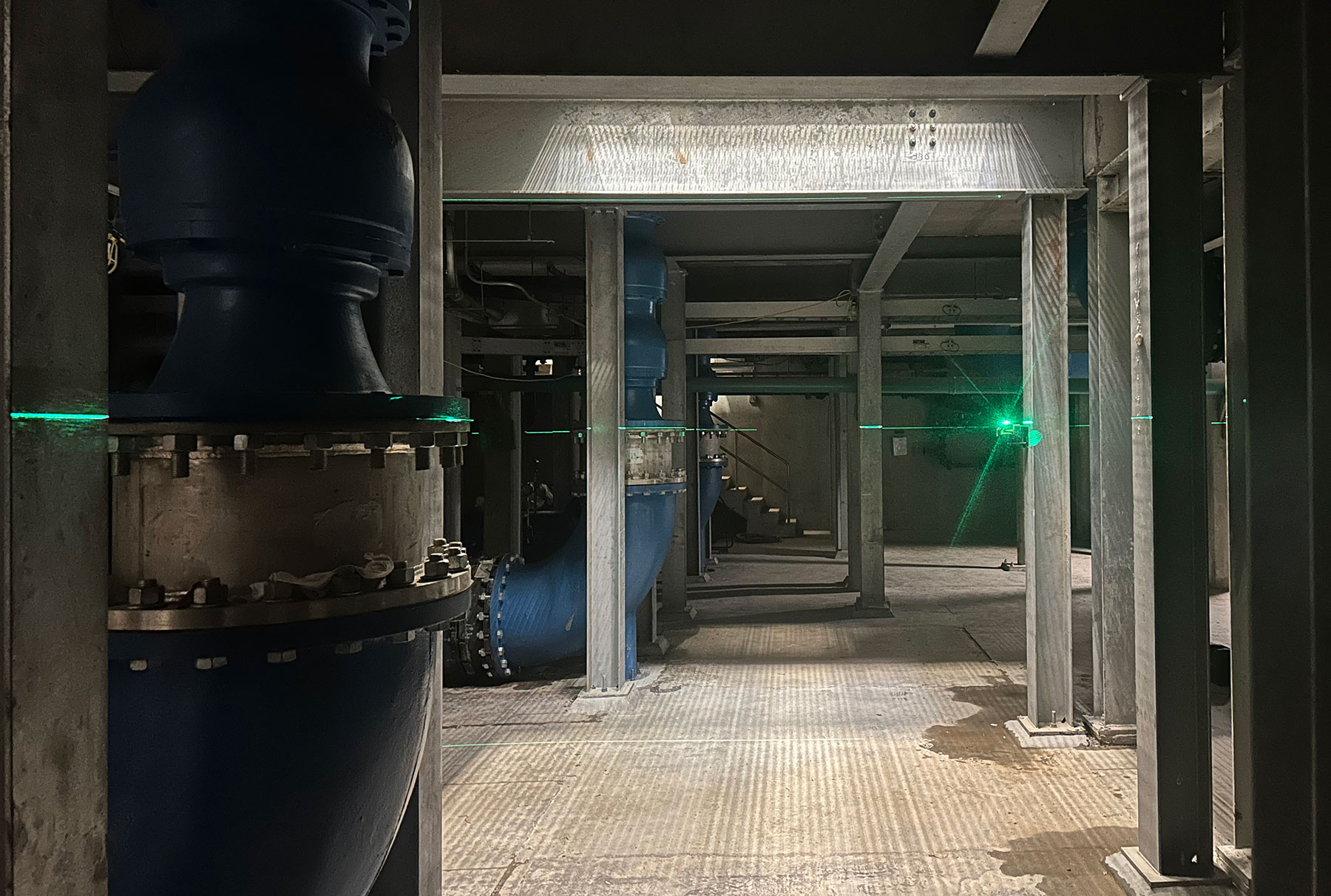

- There were multiple phases of work with immense precision requirements – notably the alignment and leveling between the previously cast-in-place concrete pads and piping with the pumps. An important quality control tool the crew utilized was an automatic laser level to help visually align the pumps with the numerous fittings that had extremely limited tolerances and flexibility.

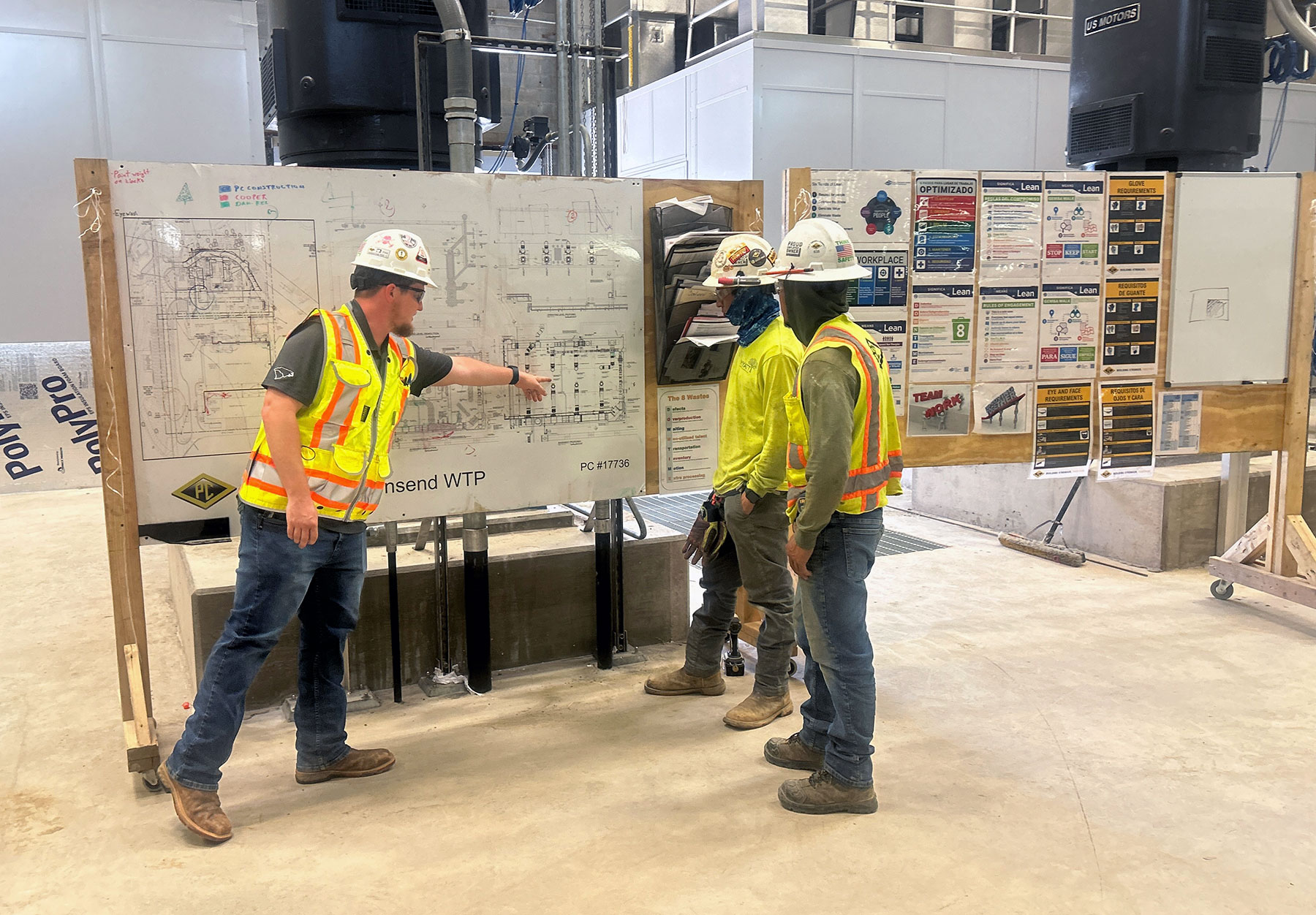

- We developed custom large-format visuals mounted on wheeled carts to communicate our plans and processes. This was a very complicated scope and sequence of work, and we immediately saw the visual usage take off. We used them daily for our safety and Lean planning with our 20+ member process piping crew, but they also became a critical communication tool with plant operations, the design team, inspectors and other trades. These visual tools allowed the work to take place safely and with the high level of coordination needed.

- With no crane access in the building, our team was very creative with rigging and hoisting. We leaned heavily on dollies, chain falls and come-alongs to complete the work. Many times, while on a tight shutdown, rigging like this is strewn in gangboxes or even a five-gallon bucket. Before our work in the field started, the team built mobile tool and equipment carts for chain falls and come-alongs and another for wrenches and sockets. With this organized setup, we saw elevated production rates and the highest quality installation.

My piping crew and I are extremely proud of this work. This high-precision process mechanical and equipment work took many months to plan and was executed on schedule and without incident. The entire team was open-minded and willing to implement new ideas, which allowed us to overcome a very challenging scope of work with tight plant operational constraints to complete this major pump station upgrade successfully.