The PC Construction team has achieved a critical milestone on the Bioenergy Facility project at WSSC Water’s Piscataway WRRF – the completion of the first annual maintenance of the Cambi B6-4 Thermal Hydrolysis Process (THP) and switchover to the redundant module.

The PC Construction team has achieved a critical milestone on the Bioenergy Facility project at WSSC Water’s Piscataway WRRF – the completion of the first annual maintenance of the Cambi B6-4 Thermal Hydrolysis Process (THP) and switchover to the redundant module.

The Cambi THP is a major component of the $270 million Bioenergy Facility and serves as a pre-treatment process upstream of anaerobic digestion, utilizing high temperature and pressure (375°F at 170 psi) to break down organic matter in the municipal wastewater sludge. This process enhances the biodegradability of the material, leading to increased biogas production and improved dewatering of the resulting Class A biosolids, all while reducing the volume of residual solids requiring offsite disposal. This particular facility is unique in that it is the first THP facility in the world to incorporate Cambi’s ‘redundant modules’, providing WSSC Water a full backup system in case a singular unit experiences failure.

The new Bioenergy Facility has been in operation for just over a year with operation and preventative maintenance tasks performed by WSSC Water. To ensure optimum performance and long-term reliability, Cambi requires the unit be taken out of service annually for maintenance, requiring a full shutdown. During that time, piping is taken apart and manways to the vessels are opened to properly clean and remove solids deposition. Pressure relief valves and the seats on the sludge and steam valves are also replaced.

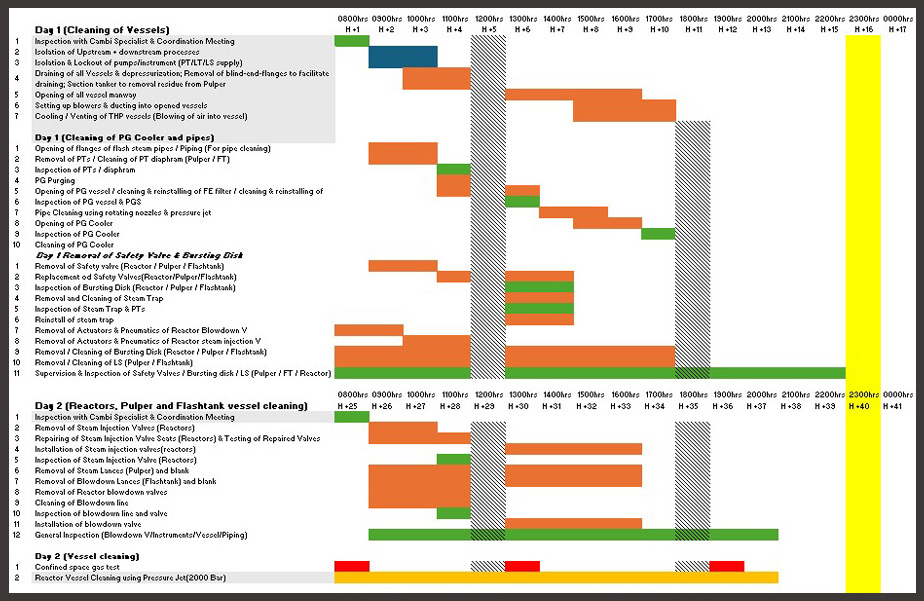

Prior to the shutdown, the facility was processing over 65 dry tons of biosolids each day. Extensive coordination and pre-planning were required with WSSC Water operations staff located at the main Piscataway WRRF facility as well as the four other WSSC Water treatment plants that truck biosolids to the site. A shutdown and maintenance plan along with a detailed hour-by-hour schedule for the planned seven-day shutdown was developed, outlining individual work tasks and identifying which member of the integrated team was responsible for each task. PC Safety Specialist Mark Becker was also instrumental in working with Cambi and WSSC Water during this stage of the operation to address the work exposures of stored energy, high steam pressure and high temperatures. After multiple pre-planning sessions, the final plan review was held two days before shutdown initiation.

This was an intensive, collaborative effort involving all team members. The primary operation was led by Cambi with PC Construction providing administrative, safety and mechanical support and WSSC Water stepping in with operational oversight and additional mechanical support. In addition, Jet Blast provided high pressure washing and vacuum trucking services for the cleaning and flushing of the piping and vessels.

Special thank you to PC Construction’s awesome “Tear Down, Bolt-up, and Turn & Burn Team” whose expertise and talents contributed significantly to this successful outcome: Emanuel “Mocco” Negron, Alejandro “Yoyo” Vargas, Luis “Catracho” Rivera, Luis Rivas, Betzaida “Bee” Reyes and Gilberto “Shorty” Reyes. Cambi’s Dawn Taylor said it best: “I genuinely enjoyed working onsite with Mark, Mocco, and his crew. Their professionalism and teamwork truly stood out. Mocco and his team put in long, demanding days to accomplish a significant amount of work, all while maintaining a positive attitude and strong dedication.”

Following the safe and successful completion of maintenance, the THP was returned to service utilizing the redundant system one day ahead of schedule, a testament to the extensive planning and incredible team effort every member brought to the table. This milestone not only marks a successful first-year maintenance cycle but also reinforces the strength of collaboration, planning and technical excellence that has defined the entire Bioenergy Facility project.

A snapshot of the first two days of shutdown maintenance work, scheduled by the hour.